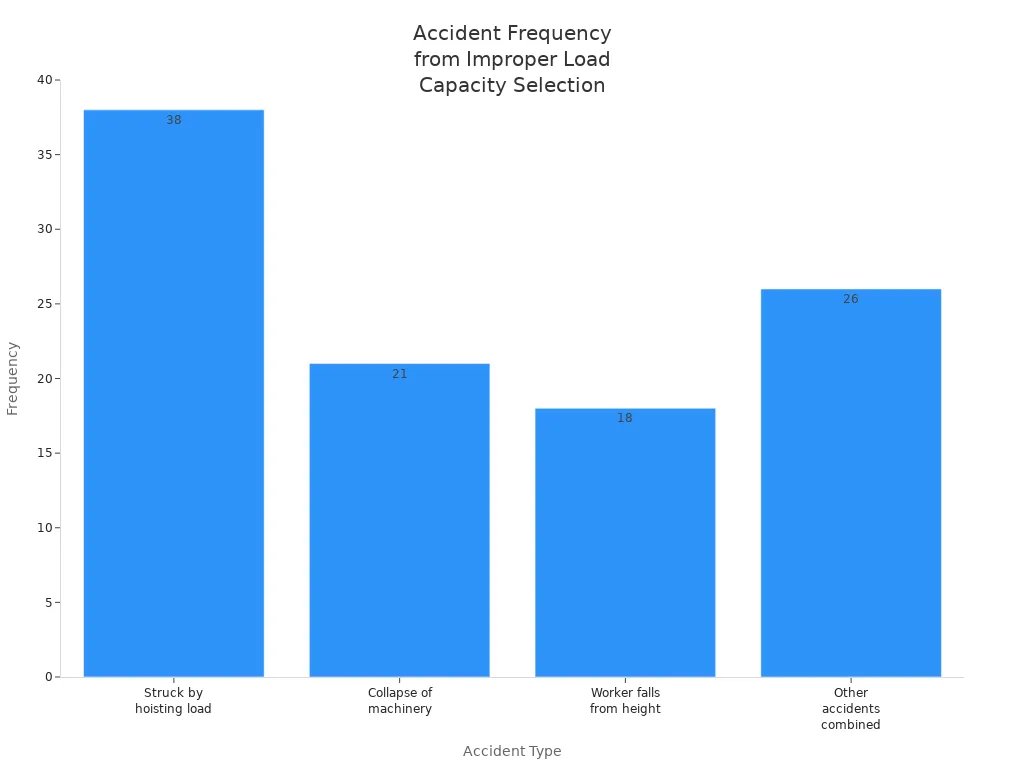

Understanding load capacity is crucial for anyone using magnetic wall hooks. It directly influences how safely they can hang items. Choosing the right magnetic wall hooks, including options like refrigerator hooks and small magnetic hooks, ensures that people avoid accidents and maintain functionality. For instance, improper selection of magnetic hanging hooks can lead to serious accidents, like being struck by a falling load.

Key Takeaways

- Understand load capacity to ensure safety when using magnetic hooks. Always check the weight ratings before hanging items.

- Consider factors like the type of magnetic material and surface characteristics. These elements significantly affect how much weight a hook can hold.

- Regularly test and maintain your magnetic hooks. This practice helps ensure they remain reliable and safe for use over time.

What is Load Capacity?

Load capacity is a term that describes the maximum weight a magnetic hook can support when it’s in direct contact with a magnetic surface. This definition is crucial for anyone using magnetic wall hooks. When you hang something on a hook, you want to ensure it stays put and doesn’t fall.

The load capacity can change based on several factors. For instance, if the load is applied downward, the pull becomes indirect. This situation requires additional calculations to determine the effective load capacity. Understanding these nuances helps users make informed decisions about which hooks to choose.

In laboratory or industrial settings, professionals measure load capacity in terms of pull force and shear force.

The load capacity for magnetic hooks is typically measured in terms of pull force and shear force. Pull force is the force required to pull the magnet directly away from a steel surface, while shear force is the force required to slide the magnet across or downward on the steel surface.

Here’s a quick breakdown of these forces:

- Pull force: This is the maximum load the magnet can hold in a straight vertical direction.

- Shear force: This is the force it takes to slide the magnet downward on a steel surface.

- The ratio of pull force to shear force depends on factors like friction coefficient, surface smoothness, and the geometry of the contact area.

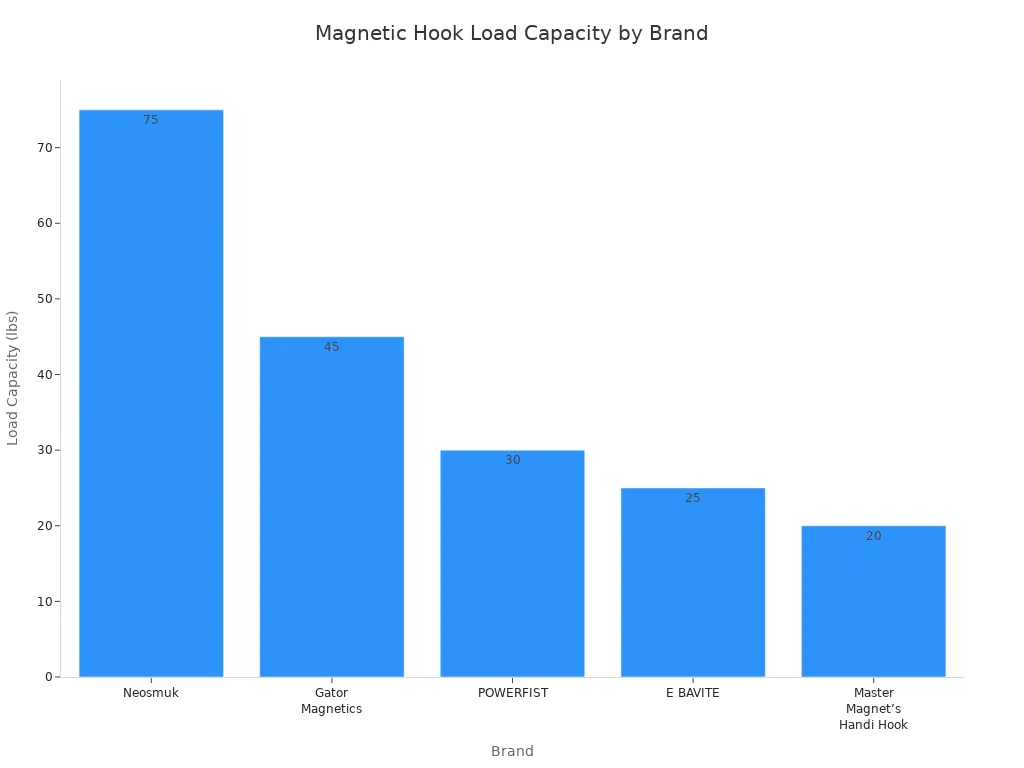

Many consumers have misconceptions about load capacity. For example, some people think that a magnetic hook rated for 50 pounds can hold that weight in typical hanging situations. However, this isn’t always true. The weight ratings often refer to pull force, which doesn’t reflect real-world performance. When weight is applied downward, the actual load capacity can be much lower. A hook rated for 45 pounds of pull force may only support less than 9 pounds when the load is applied downward.

Understanding load capacity helps users select the right magnetic wall hooks for their needs, ensuring safety and functionality in various applications.

Factors Affecting Load Capacity

When it comes to magnetic hooks, several factors influence their load capacity. Understanding these factors helps users make informed choices. Here are the key elements to consider:

- Type of Magnetic Material: The material used in the magnet plays a significant role. For example, neodymium magnets are much stronger than ferrite magnets. This strength allows neodymium hooks to support heavier loads, making them a popular choice for various applications.

- Mounting Surface Characteristics: The surface where the hook attaches can greatly affect its performance. Here are some important aspects:

- The type of metal impacts the adhesive force of the magnets.

- The thickness of the metal influences the breakaway strength.

- Coatings on the metal can alter the interaction between the magnet and the surface.

- The direction of the load, whether tension or shear, plays a role in the effective load capacity.

- The finish of the base metal affects the coefficient of friction, which is crucial for maintaining the magnet’s hold.

- Environmental Conditions: Temperature and humidity can also impact load capacity. Changes in these conditions may lead to adhesive degradation, making magnetic hooks less reliable for heavy or valuable items. Users should be cautious when using hooks in varying environments.

- Orientation of the Hook: The way a magnetic hook is positioned can change its load capacity. For instance, a vertical orientation typically has a lower shear force compared to a horizontal one. Here’s a quick comparison:

| Orientation | Pull Force | Shear Force |

|---|---|---|

| Vertical | 45 lbs | < 9 lbs |

| Horizontal | Higher | Higher |

- Exceeding Rated Load Capacity: Users should never exceed the rated load capacity of magnetic hooks. Doing so can lead to several risks:

- Hooks may slide or tilt.

- Items could drop, leading to potential damage.

- Users might lose valuable items.

- Maintenance Practices: Regular maintenance helps ensure that magnetic hooks retain their rated load capacity over time. Here are some recommended practices:

- Conduct regular inspections for visible damage or wear.

- Keep the equipment clean by removing debris.

- Lubricate moving parts as needed.

- Perform load testing to confirm the equipment can handle its rated load.

By considering these factors, users can select the right magnetic wall hooks for their needs, ensuring safety and functionality in various applications.

Testing Load Capacity

Testing the load capacity of magnetic hooks is essential for ensuring safety and functionality. Several methods help determine how much weight these hooks can reliably hold. Here are some common testing methods:

- Breakaway Testing: This method checks the maximum lift capacity under ideal conditions. It involves a thorough visual inspection and functional testing to comply with ASME B30.20 standards.

- MDFA Pull Test Standard: This test measures the normal force needed to detach a magnet from a surface. It applies a gradually increasing load until the magnet separates from the test plate, defining the breakaway force.

- Holding Force Measurement: This method assesses the holding force of a magnet against a test plate. It applies to both electro and permanent magnets.

Manufacturers certify the load capacity ratings through rigorous testing processes. For instance, they often perform pull-off tests, gradually increasing the force until they verify the maximum load. The EN 13155:2020(E) standard requires that the load capacity must be 2x to 3x higher than the nominal value, ensuring safety coefficients are met.

Regular testing, typically performed annually, helps maintain reliability. By understanding these testing methods, users can confidently choose the right magnetic wall hooks for their needs, ensuring they can safely hang items without worry.

Common Uses for Magnetic Wall Hooks

Magnetic wall hooks serve a variety of practical purposes in homes, offices, and industrial settings. Their versatility makes them a popular choice for organizing and displaying items. Here are some common uses:

- In Residential Spaces:

- People often use magnetic hooks in garages, kitchens, and bathrooms.

- They hang keys, pictures, and indoor tools with ease.

- Cleaning equipment like brooms and mops find a perfect spot on these hooks.

- In Commercial Settings:

- Businesses utilize magnetic wall hooks for various organizational needs.

- They display photographs, organize kitchen essentials, and store tools in sheds or garages.

- These hooks keep keys within reach and help manage crafting supplies.

- In Industrial Environments:

- Heavy-duty magnetic wall hooks can support significant weight, making them ideal for hanging lights, wires, and cords.

- They help organize tools and equipment in warehouses, keeping workspaces neat and efficient.

The load capacity of these hooks varies based on their intended use. For example:

| Hook Type | Load Capacity (lbs) | Common Uses |

|---|---|---|

| Light-duty | 5-10 | Keys, towels |

| Medium-duty | 15-25 | Retail applications |

| Heavy-duty | 50+ | Industrial use |

Light-duty hooks are perfect for lightweight items, while heavy-duty options can handle more substantial loads. Understanding these differences helps users select the right magnetic wall hooks for their specific needs.

Comparing Light-Duty vs. Heavy-Duty Hooks

When choosing magnetic hooks, understanding the difference between light-duty and heavy-duty options is essential. Each type serves specific needs based on load capacity and intended use.

Light-duty hooks typically support lighter items. They can hold up to 35 lbs, making them perfect for everyday tasks. People often use them for hanging kitchen utensils, cleaning equipment, or even keys. Here’s a quick look at their specifications:

| Type of Hook | Load Capacity (lbs) | Applications |

|---|---|---|

| Light-duty hooks | Up to 35 lbs | Kitchen utensils, crafting supplies, cleaning equipment, keys, clothing |

On the other hand, heavy-duty hooks are designed for more demanding tasks. They can support loads of up to 112 lbs. These hooks find their place in commercial and industrial settings, where they hold tools, cables, and even banners. Here’s how they stack up:

| Type of Hook | Load Capacity (lbs) | Applications |

|---|---|---|

| Heavy-duty hooks | More than 35 lbs | Commercial, industrial, technical settings, supporting wires, tools, cables, banners, signs, hanging lights |

In terms of construction, light-duty hooks often use lighter materials, while heavy-duty hooks feature robust designs for added strength. For example, light-duty hooks can handle up to 45 lbs shear force, whereas heavy-duty hooks can manage up to 60 lbs pull force.

Choosing the right hook depends on the weight of the items you plan to hang. By understanding these differences, users can make informed decisions that ensure safety and functionality in their spaces.

In summary, accurately determining load capacity is vital for using magnetic hooks safely. Remember these key points:

- Claims about weight capacity can be misleading.

- Performance varies based on the surface type.

Before buying, assess your needs by evaluating specifications, compliance, and support options. This ensures you choose the right hooks for your tasks!

FAQ

What is the maximum weight a magnetic hook can hold?

Magnetic hooks can hold varying weights, typically ranging from 5 to over 100 pounds, depending on their type and design.

How do I know if a magnetic hook is suitable for my needs?

Check the load capacity rating, material type, and intended use to ensure the hook meets your specific requirements.

Can I use magnetic hooks outdoors?

Yes, but consider environmental factors like temperature and humidity, which can affect their performance and reliability.

Post time: Sep-08-2025